Unraveling the Process of Wave Soldering

Wave soldering, a method predominantly used for soldering through-hole components on printed circuit boards (PCBs), has a rich history that dates back to the mid-20th century. This technique revolutionised the electronics industry by providing an efficient solution to the labor-intensive manual soldering required in early manufacturing.

The Birth of Wave Soldering

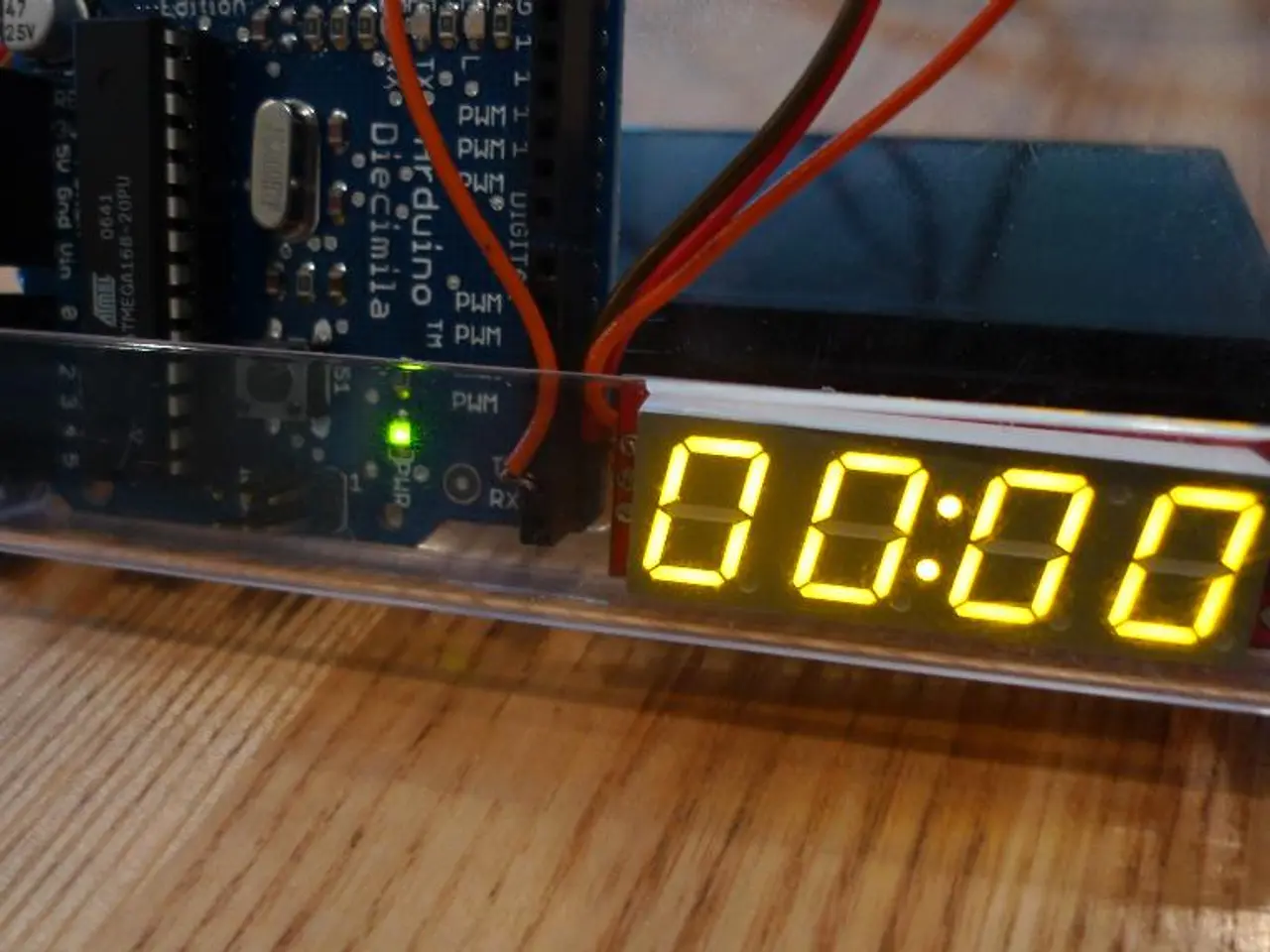

The first wave soldering machines were designed to accommodate through-hole components, replacing the slower, manual soldering of individual leads. The process involved immersing or "dipping" the board's component side in a wave of molten solder generated by a pump and a nozzle system.

The solder wave was carefully controlled to wet the leads and pads quickly without damaging components. The principle was simple: the PCB was carried over a wave of molten solder by a conveyor system, and the solder wave contacted and wet all exposed through-hole leads and pads on the board bottom. Surface tension and capillary action caused the solder to adhere and solidify once the board passed beyond the wave. Flux applied prior to soldering removed oxides and promoted solder wetting.

Evolution of Wave Soldering

As electronics evolved, so did wave soldering. The second generation of wave soldering machines introduced in-line fluxing, replacing manual fluxing, and the conveyor was tilted and the distance between baffles was increased to slow the movement of solder on the wave crest.

The third generation of wave soldering machines used an asymmetrical wave to achieve both objectives of slow separation from the solder and a barrier to oxygen. This was a significant leap forward, as it addressed the issue of excess solder caused by long leads and large pads on through-hole dual inline packages.

The Arrival of Surface Mount Devices (SMDs)

With the advent of surface mount technology (SMT), wave soldering machines had to adapt. The fourth generation of wave soldering machines was designed to accommodate SMDs, and chip waves were introduced to overcome the challenges posed by SMDs.

Despite the shift towards SMT and reflow soldering, wave soldering remains relevant for boards with through-hole technology (THT) components. It is still deployed for mixed technology boards or for the economical bulk soldering of through-hole parts.

The Future of Wave Soldering

Wave soldering, while a mature technology, continues to play a crucial role in electronics manufacturing. Its simplicity and efficiency make it an attractive option for large-scale production of through-hole components. As electronics continue to evolve, it will be interesting to see how wave soldering adapts and continues to contribute to the industry.

This is the first in a series of articles intended to take the mystery out of all aspects of soldering, beginning with the first successful method of large-scale production soldering. Stay tuned for more insights into the world of soldering!

Technology played a pivotal role in the evolution of wave soldering, as the first wave soldering machines were designed to replace slower, manual soldering of individual leads using technology to generate a controlled solder wave.

Over time, technology advancements led to the introduction of in-line fluxing, an asymmetrical wave, and chip waves in wave soldering machines, allowing them to accommodate various changes in electronics over the years.