Transformative magnetic brakes: significantly improving efficiency across multiple industries

In the ongoing quest for a greener and more efficient future, magnetic brakes are making a significant impact. These energy-efficient innovations are transforming industries, particularly in manufacturing and industrial sectors, by offering precise tension control, adjustable braking torque, and low maintenance.

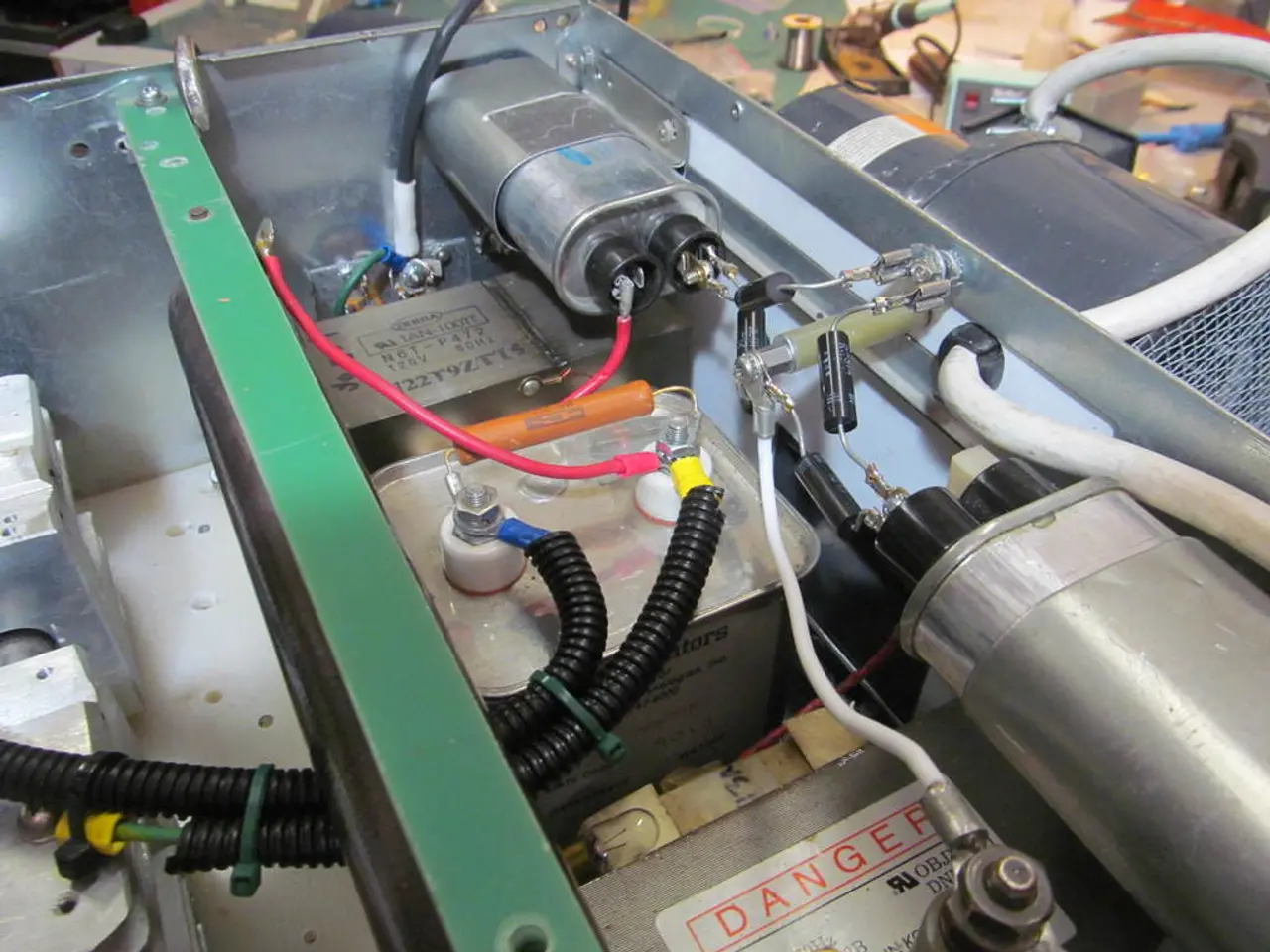

Magnetic brakes work through an electromagnet that generates a magnetic field. This field interacts with magnetic powder suspended inside the brake assembly, causing the particles to align and agglomerate, resulting in friction that resists rotation. The braking torque can be precisely controlled by adjusting the electric current in the electromagnet. This non-contact braking method reduces wear and maintenance since there is no physical friction between moving parts.

Industries that benefit from magnetic brakes are numerous. They are commonly used in applications involving material handling, packaging machines, web tension control systems, and testing equipment. Their high reliability and controllability make them valuable in automated production lines, robotics, and conveyor systems seeking consistent, adjustable braking force without mechanical wear.

Magnetic brakes also find a niche in the food processing industry, improving machinery handling and ensuring food safety. By optimizing machinery handling, magnetic brake technology can reduce contamination risks, making it a crucial component in maintaining hygiene standards.

GRW, a leader in magnetic brake technology, is at the forefront of this revolution. Their products are designed to revolutionize machinery operations in various industries, offering unmatched efficiency, reliability, and energy savings compared to conventional systems.

Advanced control systems are also being developed to allow magnetic brakes to operate with even greater precision and flexibility. These systems will enable minute adjustments with minimal lag, facilitating precise speed control.

The future of magnetic brakes is promising, with advancements pushing their boundaries further in industry automation. Research into intelligent magnetic systems that can learn and adapt to varying conditions is underway. GRW has even partnered with a manufacturing giant to develop a solution for smooth, remote, and precise machinery control.

Embracing magnetic brake technology is an investment in the future of sustainability, economy, and safety. With their incredibly long lifespan, these brakes reduce maintenance costs over time. Moreover, their energy-efficient features present significant economic benefits by minimizing energy usage and reducing maintenance needs.

In conclusion, magnetic brakes are a revolutionary technology that offers unparalleled efficiency, reliability, and energy savings. As industries continue to evolve, magnetic brakes present a potent solution for enhancing efficiency, lowering costs, and embracing the future of automation across various sectors.

Finance industries are increasingly investing in magnetic brake technology due to its energy-efficient properties and long lifespan, resulting in reduced maintenance costs over time.

Technological advancements in magnetic brakes, such as the development of intelligent systems that can learn and adapt to varying conditions, are promoting innovation and automation across multiple industries.