Apple intends to procure all American iPhones from India, transitioning production from China.

Apple's iPhone Assembly Shift: Bolstering Production in India

Tariff Tussles and Tech Giants

In an attempt to steer clear of steep tariffs due to the trade war between the U.S. and China, Apple is planing to move the assembly of all iPhones destined for the U.S. market to India as early as next year. Here's the lowdown on the situation.

Avoiding Tariffs, Diversifying Manufacturing

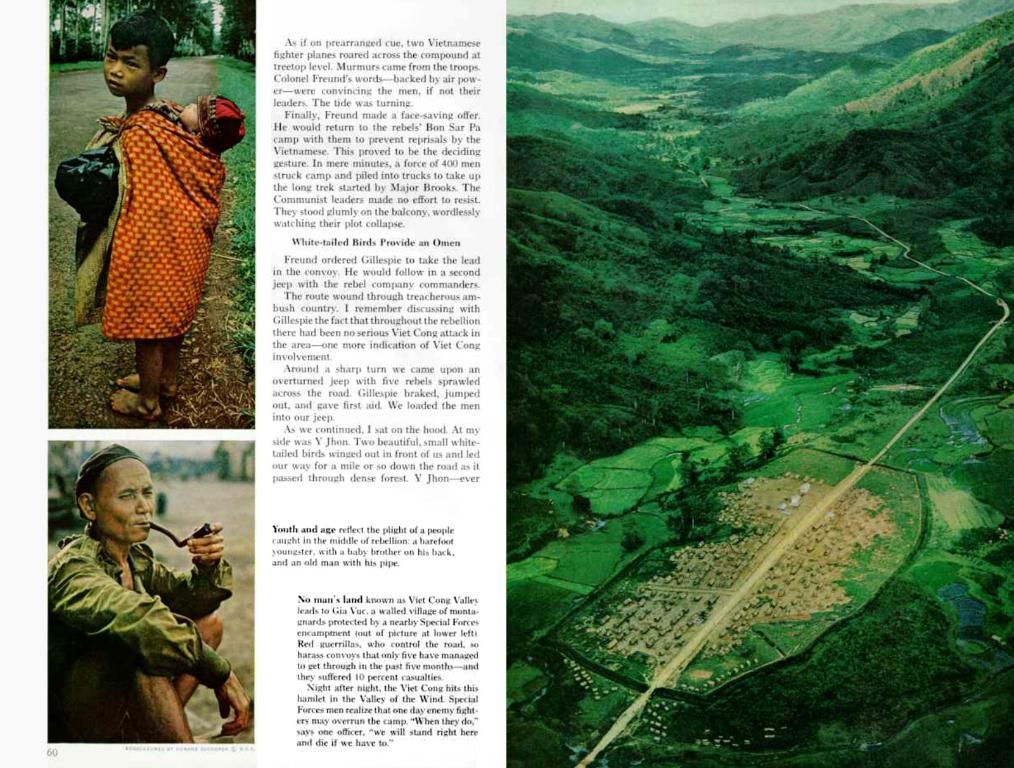

U.S. President Donald Trump's trade spat is forcing tech heavyweights to revamp their supply chains. Apple is eyeing India as a key player in its manufacturing strategy, even though local suppliers account for only a minor portion of global iPhone production at present.

Global Implications

Analysts had earlier warned that goods such as iPhones could take a heavy hit from Trump’s tariffs. With Apple heavily relying on Chinese imports, increased costs could shrink profits, giving Android phone manufacturers a leg up in competition.

Bypassing Tariffs with India's Aid

The U.S. recently granted tariff exemptions for electronics, including smartphones and computers, primarily imported from China, offering relief to companies like Apple. Now, India is garnering attention as a major hub for iPhone assembly.

The Numbers Game

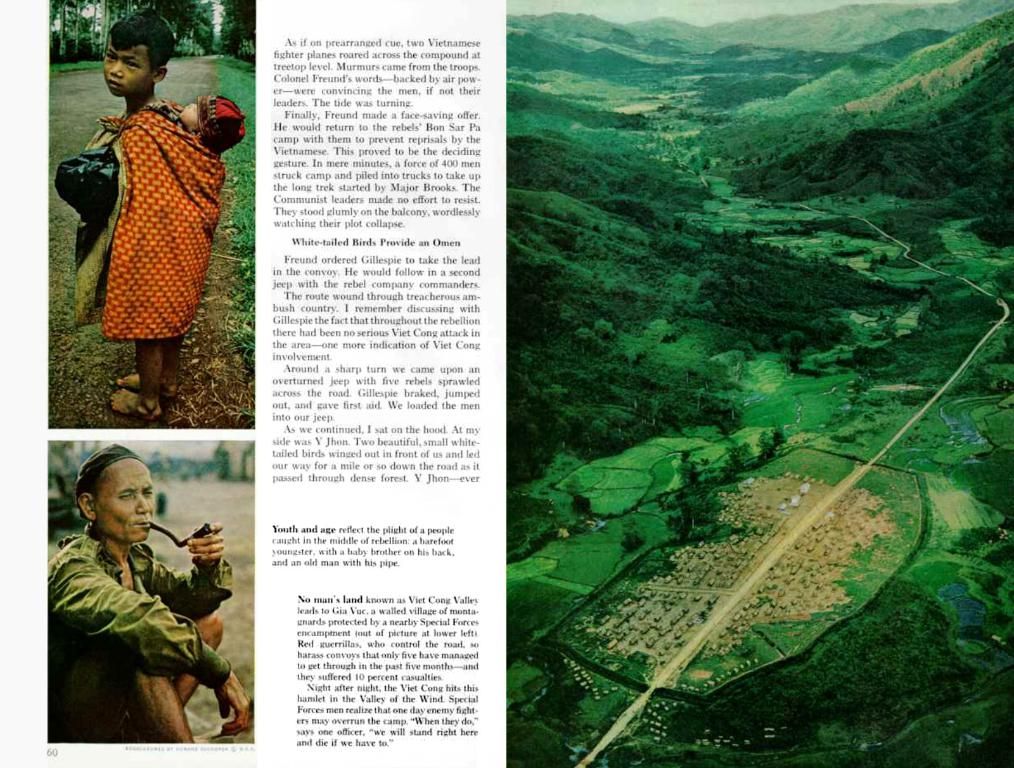

Apple sells more than 220 million iPhones annually worldwide, with around a fifth of those imported to the U.S. coming from India, and the remaining from China. Major suppliers Foxconn and Tata in India currently manage three factories, with two more under construction. In March, Foxconn and Tata shipped nearly $2 billion worth of iPhones from India to the U.S., a record high.

24/7 iPhone Manufacturing in India

To meet rising demand, Foxconn's Chennai plant has extended operations to Sundays, traditionally a day off. The plant produced 20 million iPhones in 2021, including the latest iPhone 15 and iPhone 16 models.

Challenges on the Horizon

While the iPhone assembly shift to India is progressing, Apple still depends heavily on Chinese suppliers for essential components. Migrating the entire supply chain from China is expected to take several years.

Indian Government Support

To ease the transition, India's government is offering production-linked incentives (PLI) and new subsidy plans, which are aiding Apple and its partners like Foxconn and Tata Electronics in expanding operations within the Indian borders.

[1] - Source[2] - Source[3] - Source[4] - Source

- The change in position for Apple's iPhone assembly demonstrates a strategic move to bolster production in India, as a tactic to avoid tariffs and diversify manufacturing.

- The tech industry is witnessing a shift due to finance involved in the ongoing trade tussles, with analysts predicting possible benefits for Android phone manufacturers.

- The smartphone market faces global implications with the increasing tariffs, as companies like Apple heavily rely on certain countries for their imports, and could see their profits decreased as a result.

- Despite India being a minor player at present, it is garnering attention as a major hub for iPhone assembly, earning tariff exemptions for electronics, including smartphones and computers, from the U.S.

- India's government support, through production-linked incentives and new subsidy plans, is helping companies like Apple and its partners, such as Foxconn and Tata Electronics, expand operations within the Indian borders, aiding in the transition of manufacturing positions.